I’ve seen footwell lighting in several cars, and decided it was something I wanted. I bought some LED strip lights, and made a wiring harness. I used purple wire to match the car’s lighting wire color, and black for the grounds.

My harness gets power from the glove box light. I also made the harness fit in between the stock wiring, and the glove box light switch, so I didn’t have to cut the car’s harness. My harness can be removed without any issues. The LED strip lights draw less than 1 amp, and the reduced amperage from my interior LED lights insure that I’m in no danger of blowing a fuse, or melting wire.

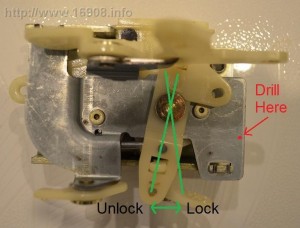

I needed a new drivers light switch since one was missing. It came with a 3-pronged piece that makes it easy to connect the car’s door lights, and the female connection on my driver’s side footwell lights.

The LED strips are simply glued with contact adhesive to the backs of the kneepads. There are two sections of strip lights on the harness, one for each footwell, and they are grounded separately at each door light switch. They work independently, depending on which door is open.

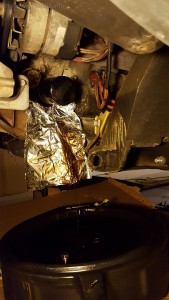

I was able to install the lighting while I had the interior torn apart a few years ago:

I think they look great at night.

Costs:

| Item | Vendor |

Quantity |

Unit Cost |

Cost |

Tax |

Total |

| 5Meter 300LEDs 3528 SMD Pure White LED Strip | eBay |

1 |

$ 5.57 |

$ 5.57 |

$ – |

$ 5.57 |

| Door Switch (too many parts to list) | DMC Midwest |

1 |

$ 15.14 |

$ 15.14 |

$ 1.17 |

$ 15.14 |

| Purple Primary Wire | on Hand |

|

|

|

|

|

| Black Primary Wire | On Hand |

|

|

|

|

|

| Female wiring connector | On Hand |

|

|

|

|

|

| Contact Adhesive | On Hand |

|

|

|

|

|

|

Total |

$ 20.71 |